| Model | BY600 | BY800 | BY1000 | BY1250 |

| Dia. of Pot | 600mm | 800mm | 1000mm | 1250mm |

| Capacity | 5~15kg | 30~50kg | 50~70kg | 90~150kg |

| Speed | 32r/min | 32r/min | 32r/min | 30r/min |

| Motor Power | 0.75kw | 1.1kw | 1.5kw | 2.2kw |

| Blower Power | 0.12kw | 0.2kw | 0.2kw | 0.55kw |

| Total Power | 1.87kw | 3.3kw | 3.7kw | 4.75kw |

| Voltage | 380V/50Hz/3Ph | 380V/50Hz/3Ph | 380V/50Hz/3Ph | 380V/50Hz/3Ph |

| Overall Dimension (L*W*H) | 780×600×1360mm | 1100×800×1680mm | 1150×1000×1680mm | 1340×1250×1680mm |

| Weight | 115kg | 270kg | 280kg | 400kg |

Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

The coating pan rotates clockwise. Compound syrup and mix slurry is jetted into the pot by several times and they are coated on the chips. The sugar coated tablets rotate in the pot. At the same time, tablet surface moisture is moved by the wind and we can get qualified sugar coated pills.

The tablet coating machine (sugar coating machine) is used to pills for pharmaceutical and sugar coating the tablets and food industries. It is also used for rolling and heating beans and edible nuts or seeds.

The tablet coating machine is widely used for making tablets, sugar-coat pills, polishing and rolling food demanded by the pharmacy industry, chemical industry, foods, research institutes and hospitals. It can also produce new medicine for research institutions. The sugar-coat tablets that are polished possess a bright appearance. The intact solidified coat is formed and the surface sugar's crystallization can prevent the chip from oxidative deterioration volatilization and cover the improper flavor of the chip. In this way, tablets are easier to be identified and their solution inside human stomachs can be lessened.

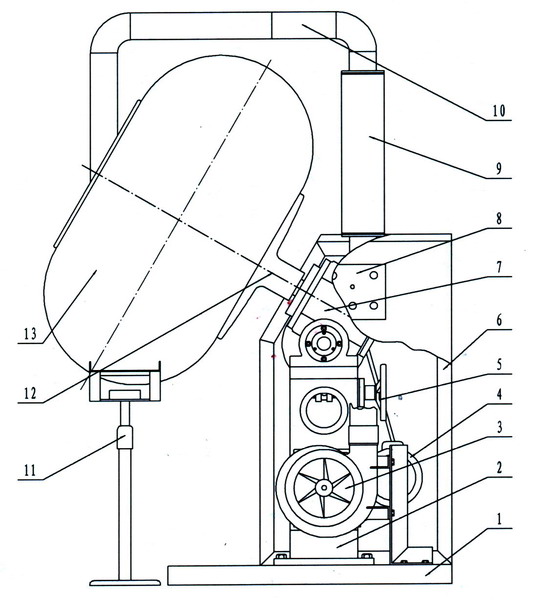

1. Base 2. Body 3. Blower 4. Motor 5. Inclination device 6. Cover 7. Speed reducer 8. Electrical control panel 10. Wind pipe 11. External heating device 12.Tray 13. Pot