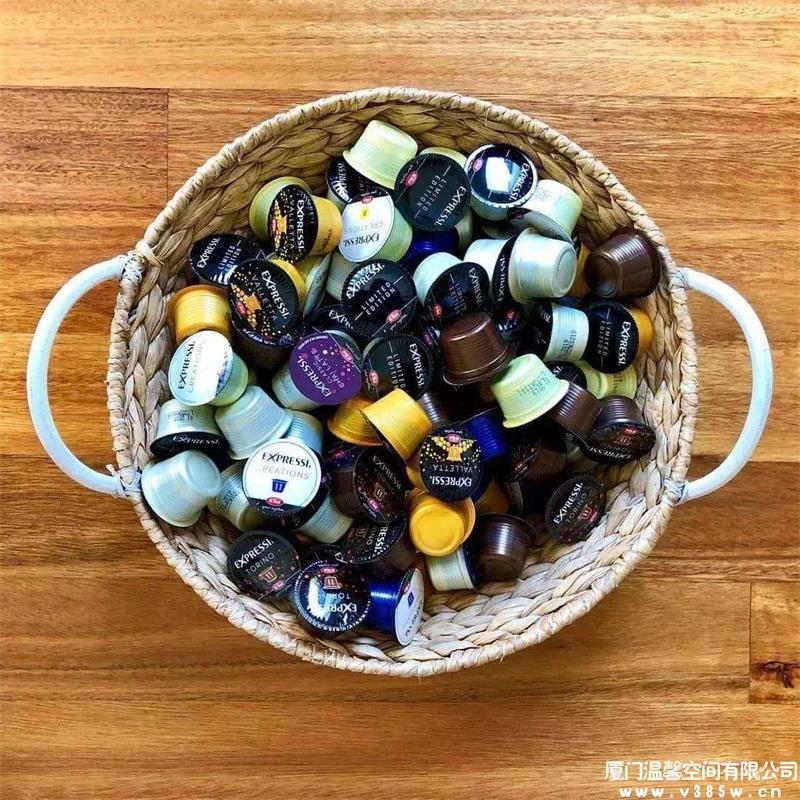

The coffee capsule filling machines are specifically designed for the needs of specialty coffee packing to provide more possibilities to ensure the freshness and shelf life of coffee capsules. The compact design of these coffee capsule filling machine allows for maximum space usage whilst saving labor cost.

| Machine parts | All the product contact parts are food grade stainless steel AISI 304. |

| Certification | CE, SGS, ISO 9001, FDA, CSA, UL |

| Product | Fresh ground coffee; instant coffee; tea products; other food powder |

| Capacity | 45-50 Pieces /per minute |

| Coffee feeding | Auger filler driven by servo motor |

| Filling accuracy | ±0.15g |

| Filling range | 0-20 g |

| Sealing | Pre-cut lid sealing |

| Hopper capacity | 5L, around 3 kg powder |

| Power | 220V, 50Hz, 1Ph, 1.5kw |

| Compressed air consumption | ≥300 L/minute |

| Compressed air supply | Dry compressed air, ≥6 Bar |

| Nitrogen consumption | ≥200 L/minute |

| Weight | 800Kg |

| Dimension | 1900 mm(L)*1118 mm(W)*2524 mm(H) |

| Note: Compressed air and nitrogen is provided by customer. | |

● Shelves for auxiliary storage capsules/cups.

● Storage bin for 150-200 pcs capsules/cups.

● Stable separation system.

● Capsule/cup bottom holding device with vacuum.Terms of Payment:

30% deposit by T/T when confirming the order,70% balance by T/T before shipping. Or irrevocable L/C at sight.

Warranty:

12 months after B/L date.

2. Empty capsule detection The light sensor is used to identify whether there are empty capsules in the holes of the mold plate for packaging, and to judge whether a series of mechanical actions such as subsequent filling are performed.

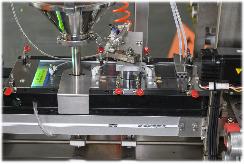

2. Empty capsule detection The light sensor is used to identify whether there are empty capsules in the holes of the mold plate for packaging, and to judge whether a series of mechanical actions such as subsequent filling are performed. 3. Filling system ● Auger filler driven by Servo motor.

3. Filling system ● Auger filler driven by Servo motor. ● Constant speed mixing device ensures that the density of coffee is always uniform and there is no cavity in the hopper.

● Visualized hopper.

● The whole hopper can be pull out and moved for easy cleaning.

● Special filling outlet structure ensures stable weight and no powder spreading.

● Powder level detection and vacuum feeder automatically convey powder. 4. Capsule/cups top edge clean-up and tamping

4. Capsule/cups top edge clean-up and tamping ● Powerful vacuum clean-up device for top edge of capsules/cups to get a good sealing eefect

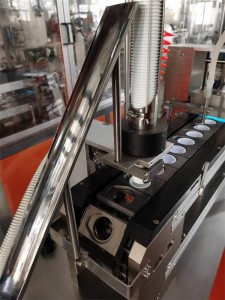

● Pressure adjustable stamping, it compacting powder strong, when brew coffee, it will get a good espresso.extrac more crema. 5. Precut lids stack magazine ● Vacuum sucker will Pick lids from stack, and place precut lids on the top of capsules. It can load 2000 pieces precut lids. ● It can dispense lid one by one, and place lids on the capsule's top precisely, guarantee lids in the center of capsule.

5. Precut lids stack magazine ● Vacuum sucker will Pick lids from stack, and place precut lids on the top of capsules. It can load 2000 pieces precut lids. ● It can dispense lid one by one, and place lids on the capsule's top precisely, guarantee lids in the center of capsule. 6. Heat sealing station After lid was placed on the capsule's top, it will has lid sensor to check if has lid on the capsule's top, then heat seal lid on the capsule's top, sealing temperature and pressure can be adjusted.

6. Heat sealing station After lid was placed on the capsule's top, it will has lid sensor to check if has lid on the capsule's top, then heat seal lid on the capsule's top, sealing temperature and pressure can be adjusted.

7. Finished capsules/cups discharging

7. Finished capsules/cups discharging ● Stable and orderly grab system.

● Precise rotation and placement system.

● (Optional) Pick and place finished capsule on the 1.8 meters conveyor belt. 8. Vacuum feeding machine Automatically transfer powder through pipe from holding floor tank to 3kg capacity auger hopper. When hopper is full of powder, vacuum feeding machine will stop work, if less, it will add powder automatically. Keep Permanent nitrogen level inside system. 9. Reject Sub-quality products

9. Reject Sub-quality products If capsule without filling powder, and capsule without lids sealing, Drop out off conveyor. It will be reject to scrap box, it will be recycable use.

(Optional) If add check weigher function, incorrect weight capsule will be rejected into scrap box. 10. Nitrogen input system and protected device Use organic glass to cover the mold, from empty capsule feeding station to sealing lids station ,all process are flushed with nitrogen. Besides, powder hopper also have nitrogen inlet, it can guarantee coffee production is under the motified atmoshpere, it will reduce each capsule's residual oxygen content lower than 2%, keep coffee aroma, prolong coffee shelf life.

10. Nitrogen input system and protected device Use organic glass to cover the mold, from empty capsule feeding station to sealing lids station ,all process are flushed with nitrogen. Besides, powder hopper also have nitrogen inlet, it can guarantee coffee production is under the motified atmoshpere, it will reduce each capsule's residual oxygen content lower than 2%, keep coffee aroma, prolong coffee shelf life.